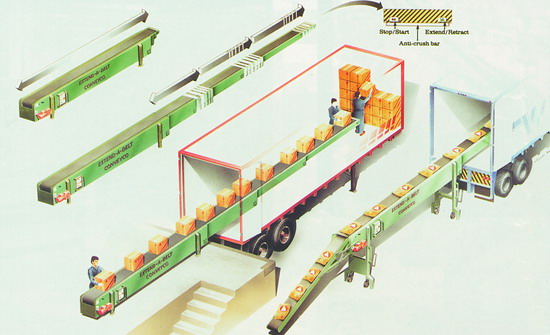

Extend-A-Belt® Telescopic Belt Conveyors

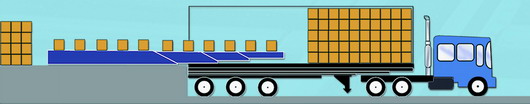

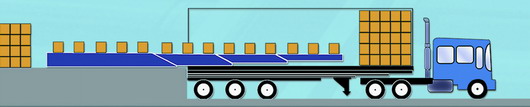

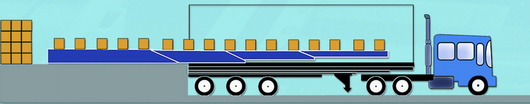

The extend-a-belt® telescopic belt conveyors are designed to simplify and partially automate material handling processes. This type of conveyor can be extended and contracted in order to more easily load and unload a variety of different products. They can cover long or short distance, be powered or unpowered and transport a wide variety of materials.

These conveyors are designed to use flat belts so they are typically best suited to moving boxes, pallets, and large items such as tires. Unlike stationary conveyor designs, the telescopic conveyor is a conveyor that can be continually reconfigured to fit the needs of the job at hand.

The primary purpose of a extend-a-belt® telescopic belt conveyor is to save companies on labour and turnaround time. Not only can the number of staff and labour hours be reduced, but quick turnaround times could mean that less factory or warehouse space is required. This is due to the fact that these conveyors can be extended all the way into trucks, allowing items to be loaded much more easily, with a minimum of walking back and forth.

The extend-a-belt® telescopic belt conveyors are most commonly found in shipping and receiving centres, warehouses, and other locations where it is necessary to move packages and other items in and out of trucks and shipping containers. In addition to extending and contracting, some telescopic conveyor designs can also be inclined up or down.

The extend-a-belt® telescopic belt conveyors are most commonly found in shipping and receiving centres, warehouses, and other locations where it is necessary to move packages and other items in and out of trucks and shipping containers. In addition to extending and contracting, some telescopic conveyor designs can also be inclined up or down.

Some models of the extend-a-belt® telescopic belt conveyor is also capable of being angled up or down as well, in addition to extending and contracting. This functionality is typically used to account for the potential height differences between truck beds and shipping docks.

These models have variations that include:

- Hydraulic elevations

- Self propelled or manual side traversing

- Side transfer rails

Some models of the extend-a-belt® telescopic belt conveyor is also capable of being angled up or down as well, in addition to extending and contracting. This functionality is typically used to account for the potential height differences between truck beds and shipping docks.

These models have variations that include:

- Hydraulic elevations

- Self propelled or manual side traversing

- Side transfer rails

A scheduled maintenance plan can extend the life of your conveyors, make them more reliable and help prevent expensive down time.

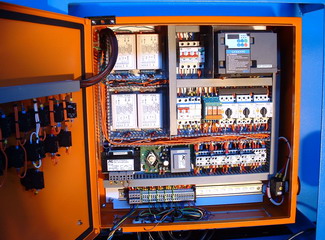

N.B. Latest models include remote wireless control front panel features

|

|

|

BENEFITS OF THE EXTEND-A-BELT® TELESCOPIC BELT CONEYOR

- Most efficient means of loading & unloading trucks or containers.

- Specially designed for moving boxes, cartons, pallets and large items

- Easy to operate

- Robust

- Fully integrates with existing conveyor systems

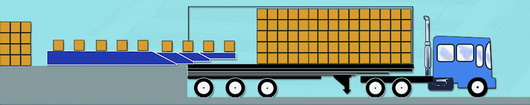

What ever the length of the container or trailer the extend-a-belt® telescopic belt conveyor simply extends or retracts as the load volume in the container increases and decreases during loading. This reduces the time and effort in this very crucial process in shipping of goods.

| Save up to 75% loading & unloading time (gaining 300% in productivity) |

|

| Simple and efficient |

|

| Conforms perfectly to established systems and practices |

|

| Pallets waste more than 10% of loading space |

|

| Extend-a-belt® extends or contracts at a push of a button |

|

SAFE AND EFFICIENT

The system is designed for ease of use. Little training is required to operate the conveyor.

However, safety is a major consideration in the design of the operation and the components.

Nose cones have been added to the front end of the conveyor and the front control panel has been moved to the side of the conveyor for increased operator safety.

The extend-a-belt® telescopic belt conveyor is designed to considerably cut loading times.

| MODEL |

CONTRACTED LEGTH |

EXTENDED LENGTH |

= EXTENSION |

STANDARD BELT WIDTH* |

Number of Segments |

| AAA | 7.5m | 22.5m | 15m | 500mm | 5 |

| AA | 7.3m | 19.3m | 12m | 500mm | 4 |

| A | 6.3m | 16.3m | 10m | 500mm | 4 |

| B | 5.3m | 12.3m | 7m | 500mm | 4 |

| C | 5.3m | 10.3m | 5m | 500mm | 3 |

| D | 5.3m | 8.8m | 3.5m | 500mm | 2 |

*Other belt widths are available (600mm, 800mm, 1000mm & 1200mm)

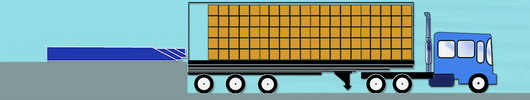

ROAD MODEL

General specification as per the Ramp Model, except for a 3.5m meter Feeder Belt increasing the unit's length. This model is mounted onto a mobile stand which provides the required working height inside the truck or container.

Model "D" does not have a front control panel and only has one extending segment.Images of Extend-A-Belt® Telescopic Belt Conveyors - Road Models

|

|

|

|

|

|

Images of Extend-A-Belt® Telescopic Belt Conveyors - Ramp Models

|

|

|

|

Follow us on: |

||||||

|

|

|

|

|

|||