Continuous Vertical Lifters

Continuous Vertical Lifters (CVL) can

automatically raise or lower product from one elevation to another. The

product is loaded and offloaded horizontally but conveyed vertically.

These conveyors provide fast, efficient,

reliable and safe product transfer between multiple floor levels. The

vertical conveying systems use conveyors which are best suited to the

kind of product being conveyed like boxes, cases, trays or bags. Even

palletized loads up to 1000kg each can be conveyed.

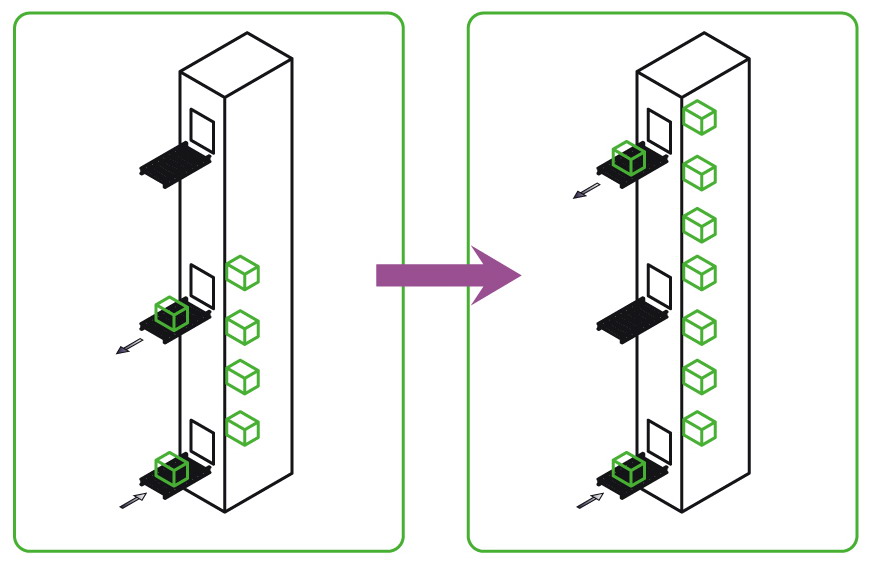

Continuous Vertical Lifters (CVL) are more suitable for a larger

capacity, as the unique carrying platform allows for continuous

uninterrupted product flow.

The CVL has an advantage over the traditional goods lift

because the CVL has multiple platforms moving continuously, while the

goods lift only has one platform that has to stop for loading and

offloading product.

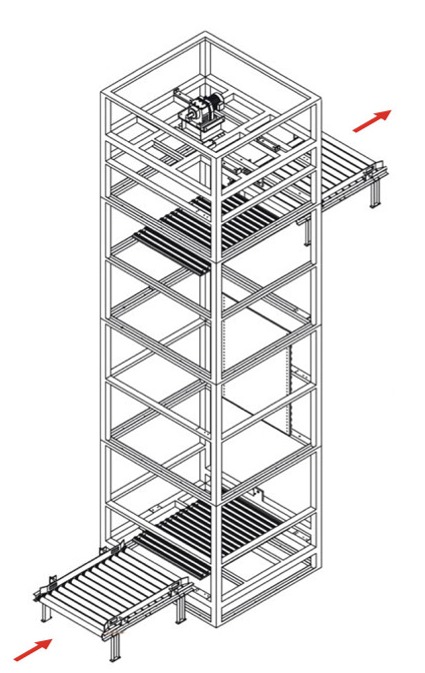

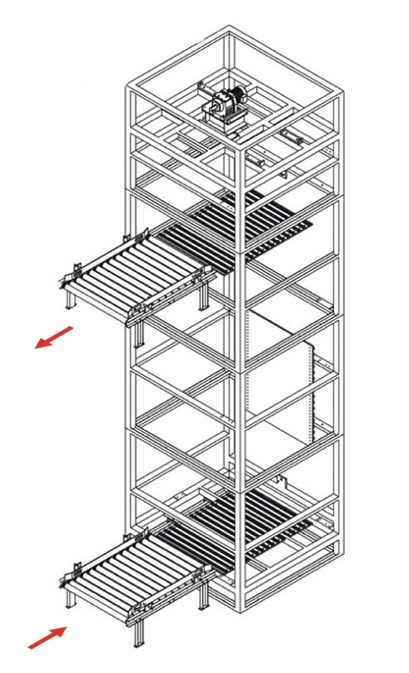

1st floor adjustable

CVL inlet is set to any floor.

CVL inlet is set on the 1st floor, outlet may be set at 2nd and 3rd floor.

1st floor fixed

The compact design of these conveyors use very little floor space

compared to incline conveyors or chutes and can be run upward and

downward.

Continuous Vertical Lifters (CVL) are used where a continuous product

flow is required for uninterrupted high volume operations.

The product is loaded horizontally, conveyed vertically and discharged

horizontally in a continuous non-stop operation.

● Small footprint

● High Speed

● Low Maintenance

● Standardised parts

● Saves labour costs

● Mass conveying between floors

● Suitable for multiple industries

● Heavy loading

● Large capacity

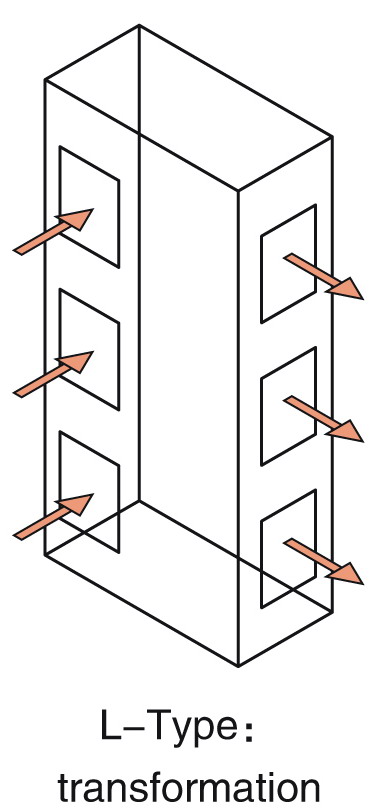

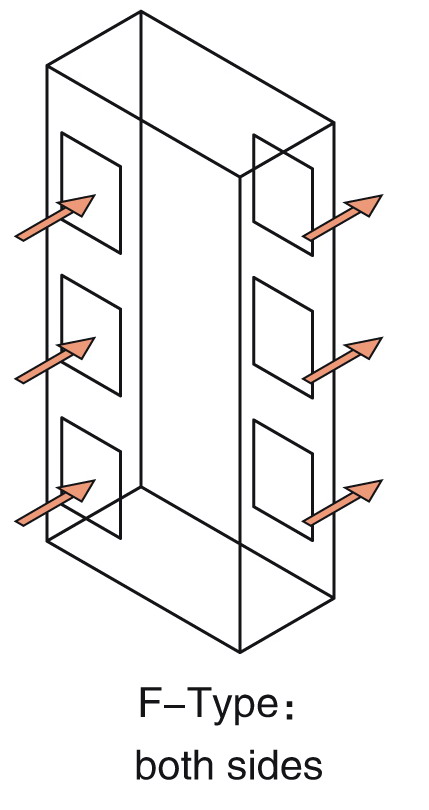

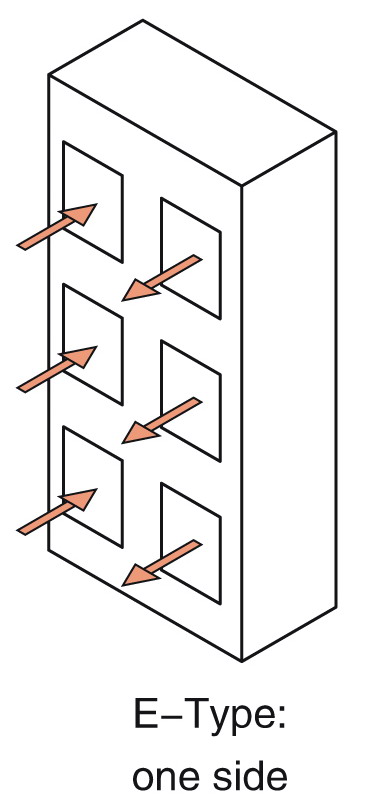

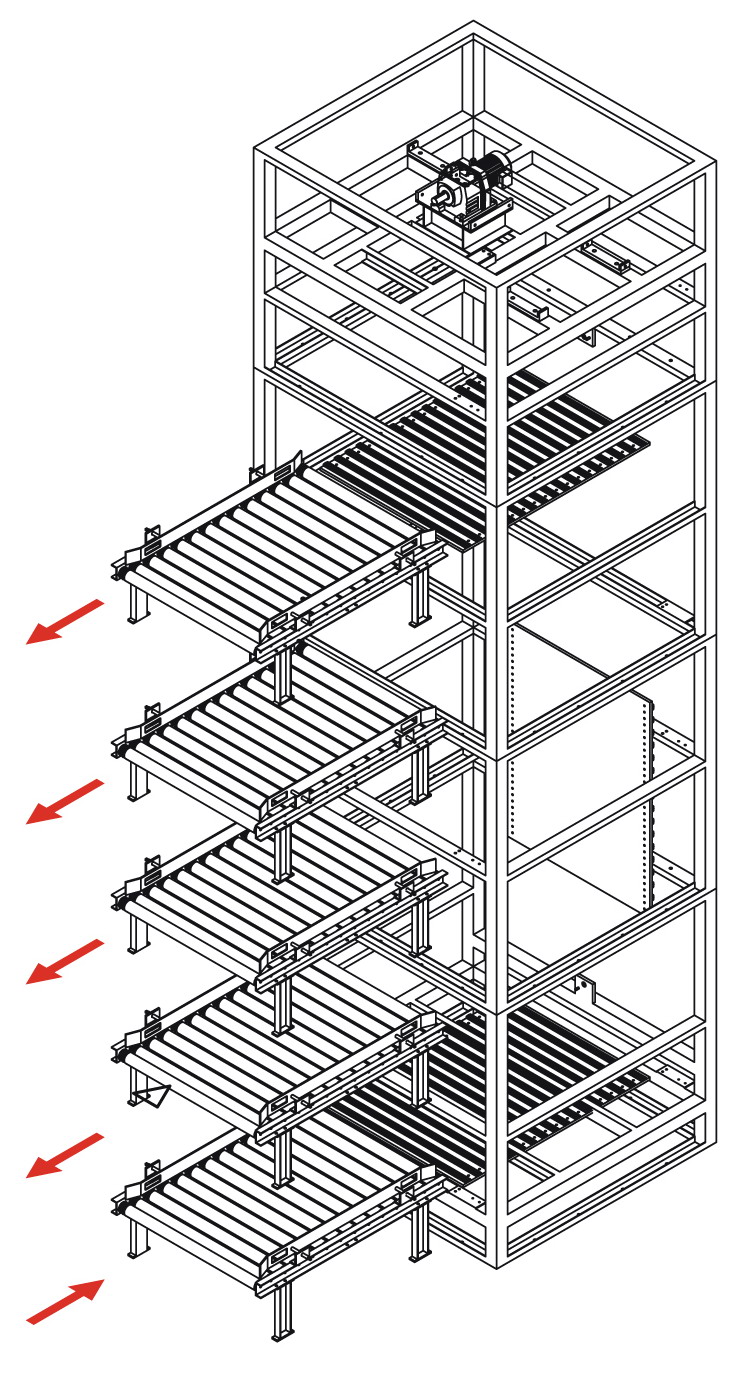

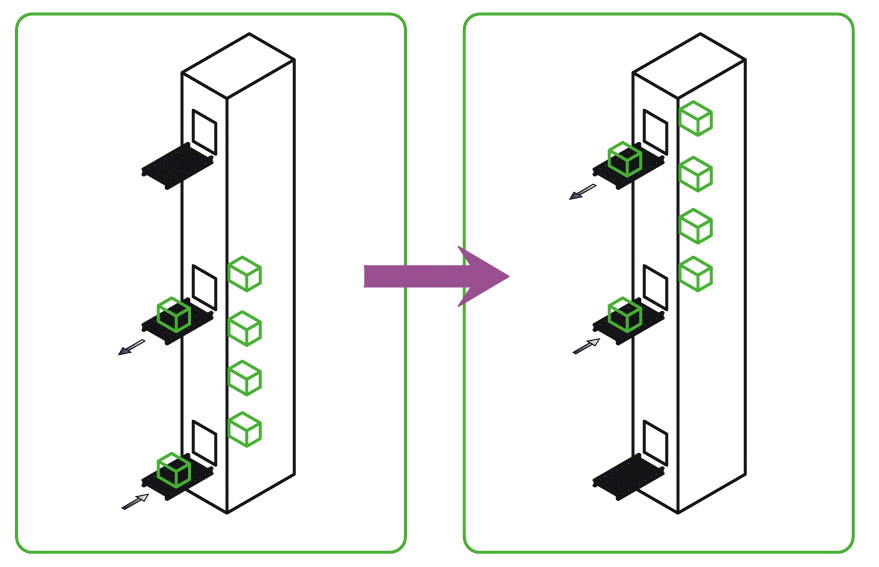

Multiple inlet / outlet continuous lifters can have various infeed or

discharge positions, making it highly efficient with a big capacity.

The inlet / outlet can be set to different floor levels on the same side

or on different sides of the lifter.

Depending on the requirements this type of lifter can achieve continuous

conveying between one floor and another.

These E-type continuous lifters are often used in large distribution

centres and can cope with complex conveying situations.

With several inlets and outlets working at the same time, matched with

bar coding, goods can be quickly and correctly sorted to the different

floors.

The inlet / outlet conveyors to the continuous vertical lifters are

synchronized to the lifting platform speed used to load / offload

product. Some of these conveyors may be roller conveyors, belt

conveyors, slat conveyors, etc.

When the inlet / outlet conveyors are too far from the loading platform

or the goods are small, transition devices can be fitted to ensure the

stability of the conveyed goods.

ROLLER CONVEYORS

The load is carried on a moving platform fastened between two continuous

loops of chain.

This platform is unique as it is rigid in the horizontal loading

position but is flexible in the opposite direction, allowing the

platform to rotate around the sprockets when returning.

The return platform tray does not interfere with the loading or

offloading of product which increases the cycle times.

When the speed of the lifter is high the surface of the carrier slats in

the platform is rubberized to increase the friction between the goods

and the carriers. This helps eliminate slippage when the goods are

entering or exiting the lifter. The smaller the product is in length &

height the faster the through put can be.

Advantages of a Continuous Vertical Lifter

The Continuous Vertical Lift is an extremely efficient, safe and reliable solution for your vertical transportation needs.

The Continuous Vertical Lifter can be used either along the edge of a mezzanine or through a hole in a mezzanine floor depending on the user's preference and the requirements. The in-feed and discharge conveyors are controlled by the photo sensors to ensure a smooth transfer.

We can supply a wide range of lifters to handle from light weight to heavy weight products. The rages available are 1kg - 20kg, 20kg - 100kg,100kg - 500kg, 500kg - 1000kg.

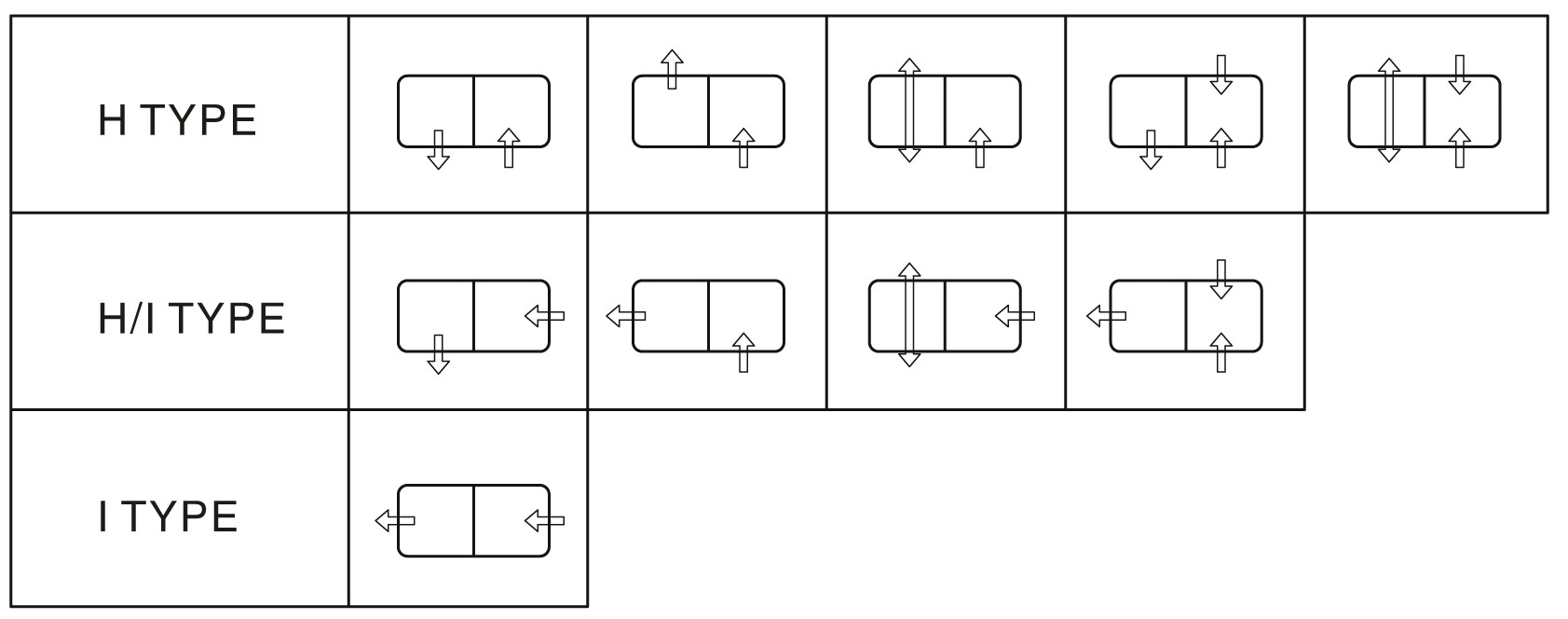

INLET / OUTLET DIRECTION DETAILED IN GRAPH

INLET / OUTLET DIRECTION TYPE

BELT CONVEYORS

|

Follow us on: |

||||||

|

|

|

|

|

|||